Talk to us

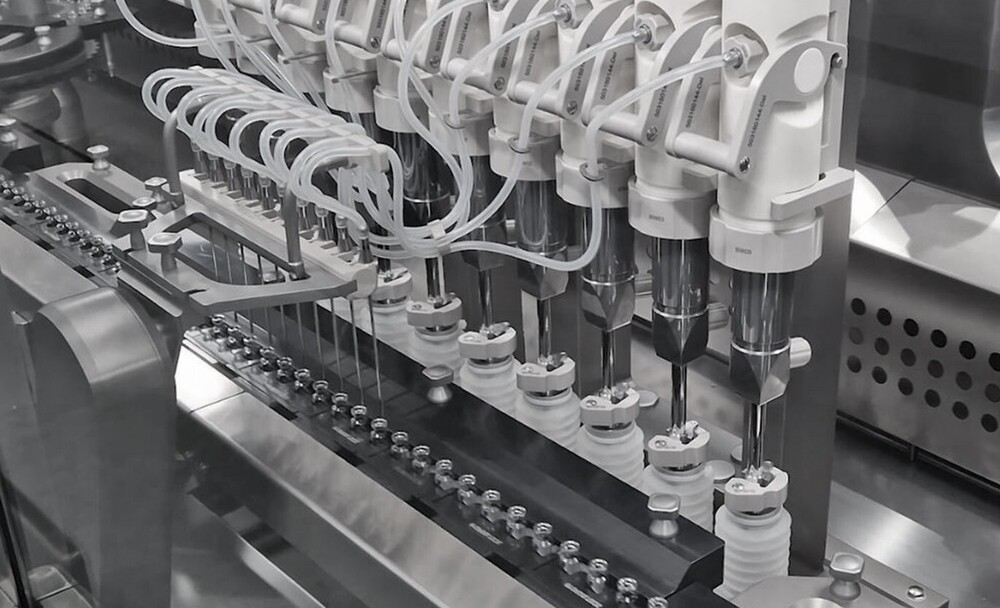

Vial Filling Machine

Price 200000 INR/ Number

Vial Filling Machine Specification

- Product Type

- Vial Filling Machine

- Application

- Food, Medical, Beverage

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Voltage

- 230 Volt (v)

- Weight (kg)

- 700 Kilograms (kg)

- Capacity

- 100 Pcs/min

- Feature

- High Performance, Low Noise, Lower Energy Consumption, High Efficiency, Stable Performance, Simple Control

- Warranty

- 1Year

Vial Filling Machine Trade Information

- Minimum Order Quantity

- 1 Number

- FOB Port

- Ahmedabad

- Payment Terms

- Cheque, Days after Acceptance (DA), Delivery Point (DP)

- Supply Ability

- 100 Per Year

- Delivery Time

- 6 Week

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- Wooden Platte Packaging or Container

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About Vial Filling Machine

-

High Precision and Accuracy: Utilizing advanced metering systems like peristaltic pumps or piston pumps, these machines ensure precise filling volumes, minimizing product loss and ensuring consistency across all vials. ï

-

Sterility Assurance: Designed to operate in cleanroom environments, vial filling machines often feature aseptic isolators or Restricted Access Barrier Systems (RABS) to maintain a sterile filling process and prevent contamination. ïAutomation and Efficiency: Modern machines are highly automated, reducing manual intervention and human error. Features such as automatic vial washing, sterilization, filling, stoppering, and capping are commonly integrated, enhancing production efficiency. ïFlexibility: Capable of handling various vial sizes and fill volumes, these machines offer versatility to accommodate different production needs. Quick changeover features allow for efficient transitions between different product runs. ï

-

Compliance and Validation: Designed to meet stringent regulatory standards like Good Manufacturing Practice (GMP) and FDA requirements, vial filling machines often come with validation support to ensure compliance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Liquid Filling Machines Category

Milk Filling Machine

Price 100000 INR / Number

Minimum Order Quantity : 1 Number

Application : Beverage, Food

Capacity : 100 Pcs/min

Warranty : 1Year

Feature : High Performance, Low Noise, High Efficiency, Stable Performance, Simple Control

Ghee Filling Machine

Price 200000 INR / Number

Minimum Order Quantity : 1 Number

Application : Food, Beverage

Capacity : 100 Pcs/min

Warranty : 1Year

Feature : High Performance, Low Noise, Lower Energy Consumption, High Efficiency

Yogurt Filling Machine

Price 200000 INR / Number

Minimum Order Quantity : 1 Number

Application : Food, Beverage

Capacity : 100 Pcs/min

Warranty : 1Year

Feature : High Performance, Low Noise, High Efficiency, Stable Performance, Simple Control

12 Station Piston Filling Machine

Price 800000 INR / Number

Minimum Order Quantity : 1 Number

Application : Chemical, Food, Medical, Beverage, Other

Capacity : 60 Pcs/min

Warranty : 1 Year

Feature : High Performance, Low Noise, Lower Energy Consumption, High Efficiency, Stable Performance, Simple Control

Send Inquiry

Send Inquiry